Winding VS Stacking: The Ultimate Comparison of Two Core Battery Manufacturing Processes

In the battery industry, there is a topic that cannot be avoided—the winding process and the stacking process.

They are the two core procedures in cell manufacturing, determining the energy density, lifespan, safety, and production efficiency of batteries. To make it easier to understand, let’s start with a simple analogy:

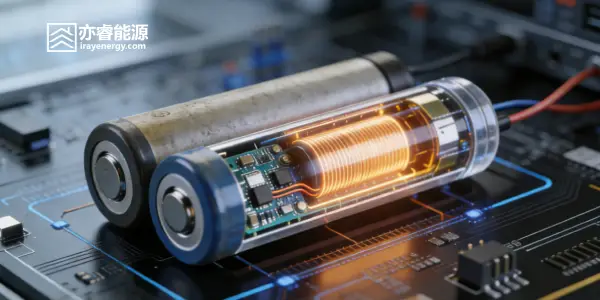

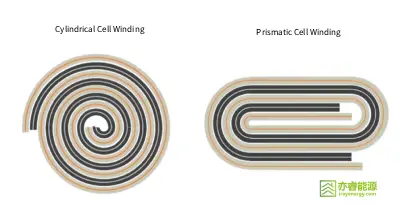

- Winding process is like rolling up a newspaper. You roll the cathode, separator, and anode layer by layer to form a jelly roll. This process is fast and continuous, but since the layers are wound with a curve, the internal stress distribution is not completely uniform.

Diagram of Prismatic Winding vs. Cylindrical Winding

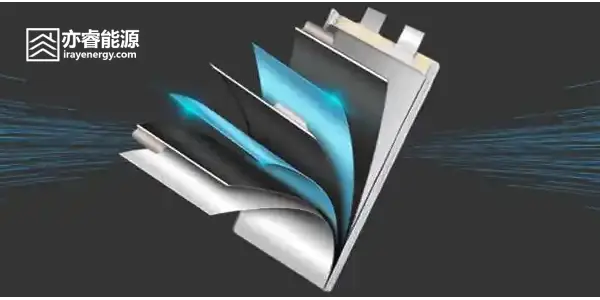

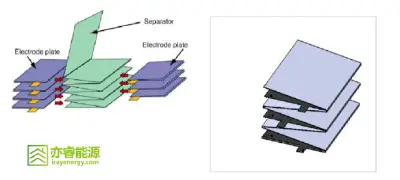

- Stacking process is like stacking sticky notes. The electrodes are cut into individual sheets in advance, then stacked alternately like a sandwich. The result is a neat, rectangular “block.” This process is precise and time-consuming, but the internal structure is highly uniform.

Comparison Diagram of Stacking vs. Winding Process

This simple analogy already contains the root cause of the advantages and disadvantages of both processes.

1. Performance Differences: Structure Determines Everything

Starting from their structural differences, winding and stacking show distinctive performance characteristics:

- Energy density: Stacking is superior.

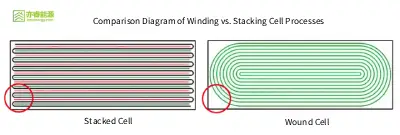

Wound cells have “dead space” at the corners due to curvature, like an unfilled corner of a box. In contrast, stacked cells are flat and layered, with minimal wasted space, allowing more active material to be packed in the same volume—resulting in longer runtime.

Comparison Diagram of Stacking vs. Winding Process

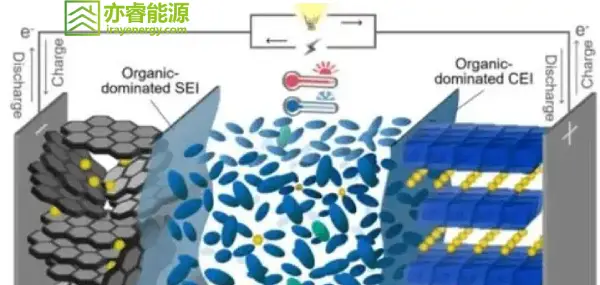

- Cycle life: Stacking is more durable.

In wound cells, stress concentrates in the curved areas, which over long charge-discharge cycles can lead to active material detachment or lithium plating, accelerating degradation. Stacked cells have a uniform stress distribution, with consistent expansion and contraction across layers, leading to longer cycle life and slower aging.

- Rate performance: Stacking also performs better.

In wound cells, the current path from the core to the tab is relatively long and curved, resulting in higher internal resistance and more heat generation at high current. In stacked cells, each layer functions like a parallel unit with shorter, uniform current paths, leading to lower resistance, higher charging efficiency, less heat, and better suitability for high-rate applications.

- Safety: Stacked cells are theoretically safer.

The uniform internal structure reduces risks of short circuits caused by uneven stress. By comparison, wound cells have potential weak points at the corners, making them slightly more prone to thermal runaway.

From these comparisons, it is clear that stacking has the upper hand in nearly all key performance metrics.

2. Process and Cost: The Battle of Efficiency

If stacking is so advantageous, why has winding dominated for so many years? The answer lies in process efficiency and cost.

- Winding: Efficient and mature

Like a high-speed printing press, winding is continuous, the equipment is mature, production speed is high, and cost is low. These advantages have long made winding the mainstream in cell manufacturing.

- Stacking: Precise but expensive

Stacking requires electrode sheets to be cut in advance, then stacked one by one with high precision. The process is complex, slower, and demands extremely precise equipment (to ensure alignment and prevent burrs). Equipment cost is also higher, resulting in overall higher manufacturing costs.

In short: winding wins in efficiency and economics, while stacking wins in performance and quality.

3. Process Choices for Different Battery Formats

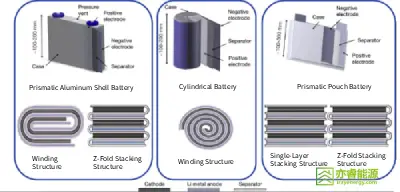

Prismatic cells: Can be made by either winding or stacking, which is why different approaches coexist in the market.

Cylindrical cells: Only winding is possible (e.g., 18650, 21700), as the geometry does not allow stacking.

Pouch cells: Usually adopt stacking, including single-layer stacking and Z-fold stacking, offering higher energy density and greater design flexibility.

These process choices explain why different cell formats show significant differences in performance and cost.

Irayenergy Winding Structure Diagram of Different Battery Types

4. Trends and Outlook: Stacking as the Future

The competition between winding and stacking essentially boils down to a trade-off between efficiency & cost and performance & quality.

Winding represents the “economical and practical” option, meeting large-scale demand at lower cost.

Stacking represents the “performance-driven” option, with higher ceilings in energy density, lifespan, fast charging, and safety—making it the future direction.

Moreover, with continuous equipment innovation, the shortcomings of stacking are being rapidly overcome.

For instance, while it once took 0.6 seconds to stack a single sheet, today’s advanced high-speed stacking machines can achieve 0.125 seconds or even faster. Cutting-stacking integrated machines and smart robotic arms are pushing efficiency and cost closer to that of winding.

This means that whenever you see a battery marketed as “ultra-long range, ultra-long cycle life, or ultra-fast charging,” chances are it uses the stacking process. Stacked cells are expanding from high-end applications toward mainstream adoption, becoming the next-generation standard.

5. Conclusion

In summary:

Winding represents maturity and cost-effectiveness.

Stacking represents performance and the future.

In the context of the energy industry’s pursuit of higher energy density, faster charging, and longer cycle life, stacking is undoubtedly the general trend. With continuous upgrades in manufacturing equipment and gradual cost reduction, stacked batteries will experience large-scale adoption in the coming years, becoming the new standard for power batteries.