In-Depth Analysis|The Power Core of Drones—A Comprehensive Exploration of Lithium Batteries

Exploring Drone Lithium Batteries: Definition, Types, Advantages, and Key Elements

As drone technology becomes increasingly popular, lithium batteries play a vital role as the core power source. A thorough understanding of lithium batteries is crucial for maximizing drone performance, ensuring flight safety, and reducing operating costs. In this article, the iRay Energy team will guide you through a comprehensive overview of drone lithium batteries, including their definition, types and characteristics, unique advantages in the drone industry, as well as key aspects such as overall parameters, connection methods, and battery pack structures.

irayenergy High-Rate Drone Battery

The Nature and Characteristics of Lithium Batteries

Lithium batteries, which occupy an important position in the modern energy field, are batteries that use lithium metal or lithium alloy as the negative electrode material and adopt non-aqueous electrolyte solutions. With their unique chemical properties, lithium batteries demonstrate outstanding performance in energy storage and release, making them the mainstream power choice across portable electronic devices, electric vehicles, and many other fields.

Lithium batteries can be divided into two main categories: lithium-ion batteries and lithium polymer batteries.

Lithium-ion batteries:

Their cathode materials are diverse, with common types including lithium cobalt oxide, lithium iron phosphate, and lithium manganese oxide. Different cathode materials give batteries distinct performance characteristics. For example, lithium cobalt oxide batteries offer higher energy density and excel in scenarios with demanding energy requirements; lithium iron phosphate batteries are well known for their excellent safety and long cycle life, making them suitable for applications with strict safety standards. Lithium-ion batteries typically use metal casings, which provide excellent sealing and mechanical strength, ensuring reliable protection for the cells inside.

irayenergy 18650 Cylindrical Battery

Lithium polymer batteries:

While their cathode materials overlap with lithium-ion batteries, their uniqueness lies in the use of solid or gel polymer electrolytes, granting them greater design flexibility. Lithium polymer batteries usually feature aluminum-plastic film packaging, which is lightweight and soft, allowing for customized shapes to fit within the compact internal space of drones. Moreover, for the same capacity, lithium polymer batteries are often lighter than their lithium-ion counterparts.

irayenergy Pouch Polymer Battery

Advantages of Lithium Batteries in Drones

Lithium batteries have become the first choice for drone power systems due to a series of outstanding advantages:

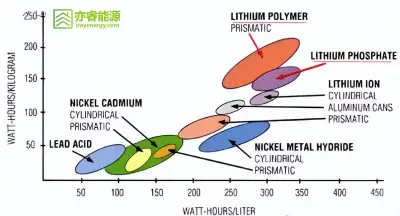

High energy density: Compared to traditional batteries, lithium batteries can store significantly more energy in a smaller volume and lighter weight. This allows drones to stay airborne for longer durations, performing more complex tasks. For instance, in aerial photography, high-energy-density batteries enable drones to cover larger areas and capture more comprehensive images; in agricultural spraying, they allow drones to monitor or spray larger farmland areas.

Energy Density Comparison Chart of Different Battery Types

- Lightweight design: Drone performance is highly weight-sensitive, and heavy batteries greatly affect endurance and maneuverability. The lightweight nature of lithium batteries reduces overall drone weight, enhancing flight efficiency and handling. For racing drones, lighter batteries enable higher speeds and more agile maneuvers.

Long lifespan: Under proper usage and maintenance, lithium batteries boast excellent durability, sustaining hundreds or even thousands of charge-discharge cycles while maintaining good performance. This is particularly important for drones used frequently, as it reduces battery replacement frequency and lowers costs.

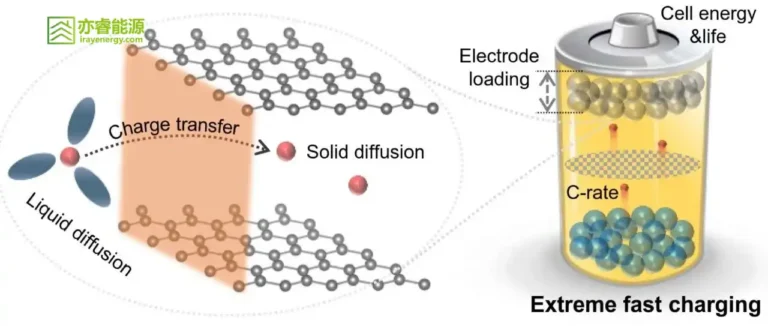

Fast charging capability: Some lithium batteries support high charge rates, allowing them to recharge in a short time. This greatly improves operational efficiency—for example, in logistics drones, fast charging enables rapid turnaround for continuous delivery tasks.

Discharge Curve Data at Different C-Rates

Key Parameters of Lithium Batteries

Capacity (mAh):

Capacity measures how much charge a battery can store. It represents how long a battery can continuously deliver 1mA of current under constant current discharge. The larger the capacity, the longer the theoretical flight time. For instance, a 5000mAh battery lasts longer than a 3000mAh battery under identical discharge conditions. However, actual endurance also depends on drone power consumption and environmental factors.Voltage (V):

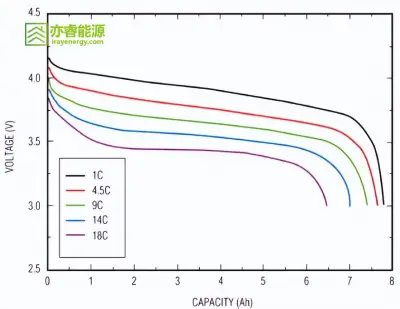

A single lithium cell typically has a nominal voltage of 3.7V or 3.8V, with actual operating voltage fluctuating within a range. Drone battery pack voltage depends on the number of cells in series. For example, a 3S pack equals 3 × 3.7V = 11.1V nominal. Generally, higher voltage batteries provide faster motor speeds and stronger power output.Discharge rate and charge rate (C):

The discharge rate refers to the ratio between discharge current and capacity, indicating how quickly a battery can release energy. The charge rate measures the charging current relative to capacity. For example, a 3000mAh battery with a 20C discharge rate supports a maximum discharge current of 60A. While high discharge rates meet drones’ heavy-load demands during takeoff, climbing, and high-speed flight, continuous operation at maximum discharge can be limited by temperature and internal resistance. Manufacturers usually recommend safe continuous discharge rates.

18650 Battery Pack Diagram

- Size and weight:

Batteries must fit drone battery compartments precisely. Improper size can prevent installation. Weight directly impacts payload and flight performance—lighter batteries improve endurance and agility. Choosing the right size and weight is essential for optimal performance.

Battery Connection Methods and Common Configurations

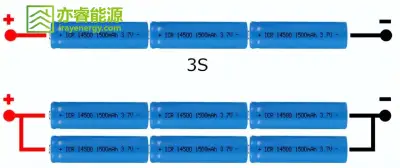

Series (S):

Connecting cells positive to negative increases voltage while capacity remains unchanged. For example, two 3.7V 2000mAh cells in series form a 7.4V 2000mAh pack. Series connections meet drones’ higher voltage demands.Parallel (P):

Connecting cells positive to positive and negative to negative increases capacity while voltage remains unchanged. Two 3.7V 2000mAh cells in parallel create a 3.7V 4000mAh pack. Parallel connections extend flight time.

Common configurations:

3S packs: Popular in small consumer drones. They balance voltage, weight, and energy density, suitable for general aerial photography and indoor flight.

4S and above: Common in professional and large drones. Higher voltage provides stronger power, ideal for heavy payload and demanding tasks. Agricultural spraying drones require 4S+ packs to maintain flight with spraying equipment. Long-range mapping drones often use 4S or 6S packs to deliver sufficient voltage and energy for stable, long-distance operations.

Battery Pack Structure and Parameter Calculations

Structure:

Battery packs are built by connecting multiple cells through welding or connectors inside protective housings. For safety, they include protection circuits and wiring. Connections must be solid and correct to avoid short circuits or hazards.Total voltage calculation:

For an nS pack, total voltage = n × nominal voltage of a single cell. For example, a 5S pack = 5 × 3.7V = 18.5V nominal.Total capacity calculation:

For parallel connections, total capacity = number of parallel cells × single cell capacity. For example, 4 × 2000mAh cells in parallel = 8000mAh total.

Conclusion

Through this comprehensive analysis of drone lithium batteries, we now have a deeper understanding of their definitions, types, advantages, parameters, configurations, and structures. This knowledge enables us to make informed choices tailored to specific drone requirements, unlocking the full potential of lithium batteries and ensuring stable, reliable power for drone operations.