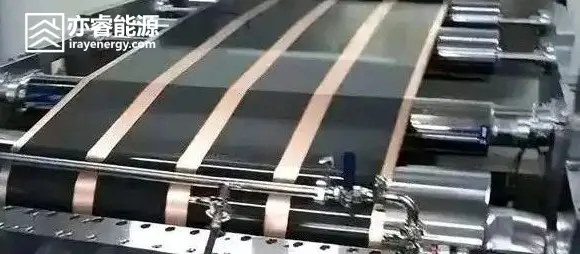

Four Common Misconceptions About the Lithium-Ion Battery Mixing Process

In the battery industry, the mixing process may look simple. But once you actually step into the slurry-preparation workshop, you’ll realize that very few people truly understand how mixing should be done. Many operators have worked for years, even more than a decade, yet their procedures remain unchanged, following old habits. They never stop to think: why do we need 8 hours to mix the same materials, while another factory only needs 3 hours?

Below, I’d like to discuss the four most common pitfalls in the mixing process, based on the typical mistakes seen across the industry.

1. Incorrect mixing procedures make the mixing time excessively long

Once, we visited a battery factory in Guangdong, China. Their slurry required at least 8 hours of mixing—excluding the degassing stage. The operator told us, “We’ve always done it this way. The viscosity is too high, so we can only mix slowly.”

But when I asked, “How much solvent do you add at the beginning?” the operator replied, “We add only about 10–20% of the liquid into the powders before starting to mix.”

At that moment, the root cause became crystal clear.

This had nothing to do with viscosity.

They didn’t understand density.

Powder has a high bulk density. The friction between dry particles is huge. Adding only 10% liquid cannot wet or disperse the powders—not to mention forming a uniform viscous system.

It’s like trying to mix a bowl of flour with one spoon of water—can you stir it? You simply can’t.

In many factories, operators mistake “high viscosity” for “hard to stir,” but in reality:

High viscosity = the powder is already wetted and forming structure—just thick

High density = the powder is too dry; real mixing hasn’t even started

Confusing these concepts traps the process in a vicious cycle:

Low liquid → Slurry won’t move → Operator lowers speed → Mixing time stretches → Low efficiency → High energy consumption → Increased cost

But with the correct liquid-adding sequence and staged powder addition, a batch of slurry can absolutely be completed in 3–4 hours.

2. Pulling vacuum throughout the entire process? This is one of the most dangerous misconceptions in the industry

Many factories believe that as long as vacuum is applied continuously, the slurry will not contain bubbles, and coating will be much easier. It sounds perfect—but in actual production, the result is the opposite.

The correct approach is: pull vacuum only after the fineness, viscosity, and uniformity have all reached their required standards.

If vacuum is applied from beginning to end, it will cause two serious consequences:

(1) The formula ratio becomes inaccurate

(1) The formula ratio becomes inaccurate

This is something many people fail to realize:

Vacuum doesn’t just remove air—it also pulls out volatile components from the liquid. The higher the vacuum level, the stronger the evaporation; the longer the mixing time, the greater the loss. The result:

Liquid content decreases → Ratio shifts → Viscosity increases → Slurry becomes more difficult to mix

Eventually, during coating:

The slurry becomes too thick

Poor leveling

Large viscosity fluctuations

Worse batch-to-batch consistency

And these issues are often hard to trace back, because people instinctively believe “vacuum must be correct.”

(2) Production efficiency drops significantly

Under vacuum, slurry volume expands and density decreases, which means:

The effective shear force of the blades decreases

Powder dispersion becomes slower

Actual mixing efficiency drops

As a result, a process that originally could be completed in 3 hours ends up taking 7–10 hours.

This is why our PE engineers at iRay Energy always say:“Vacuum isn’t about being early—it’s about being precise.”

3. Slurry splashing—an “invisible killer” that contaminates new material

Slurry splashing is a problem that many factories easily overlook.

Two typical incorrect operations cause splashing:

High-speed dispersion when the liquid level in the tank is too low

Running high rotational speed when the tank is full

Once slurry splashes onto the tank walls, residues from the previous batch may fall into the next batch of slurry. Splashes can also spread slurry throughout the planetary gearbox. Over time, this significantly shortens bearing life.

This is fatal for battery production because:

Solidified material cannot fully re-disperse

Solid particles form after coating

Electrodes may be scratched

Coating streaks, powder loss, and pinholes occur

In more severe cases, it may cause self-discharge and safety hazards

4. Improper cleaning procedures

Whenever we talk with peers in the industry, they often report that the high-speed dispersion bearings in their mixers fail very easily.

In reality, most of these failures are caused by overfilling the tank during cleaning and running the disperser at too high a speed.

When the liquid level in the tank is too high, starting the high-speed disperser will fling water into the disperser bearing housing, causing:

Water ingress into bearings

Rust

Seizure

Rapidly shortened bearing life

Although this isn’t considered a “quality issue,” it is purely improper operation, and the company bears the cost. But honestly, these losses are completely avoidable.

Finally, one more point: truly good mixing is not about how expensive the equipment is, nor how long the mixing time is. It depends on mastering:

Material addition sequence

Speed switching

Vacuum timing

Powder wetting

Viscosity control

Proper cleaning methods

Many factories mix for 7–10 hours not because they are careful, but because the process is flawed.

Professionally run companies in the industry understand:

Scientific process > Blindly extending time

Correct method > Relying on experience

If your factory is struggling with long mixing times, unstable batches, or poor coating results, start by checking these four pitfalls—you may be able to double your efficiency immediately.