Drone Battery | A Complete Analysis of Components and Supporting Equipment

In the operating system of a drone, the battery is undoubtedly the most critical core component. Like the human heart, it continuously provides power for drone flight. A deep understanding of the battery’s structure and related supporting equipment plays an essential role in ensuring efficient operation, safety, and extended service life. In this article, IrayEnergy will provide a comprehensive analysis of drone battery components and corresponding auxiliary equipment.

Core Component of the Battery — The Cell

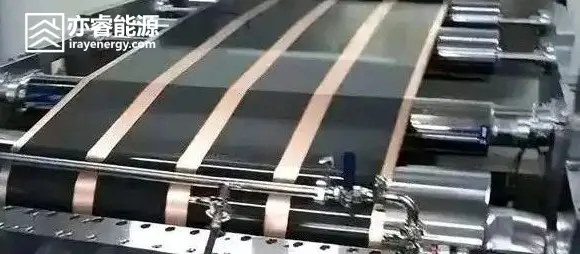

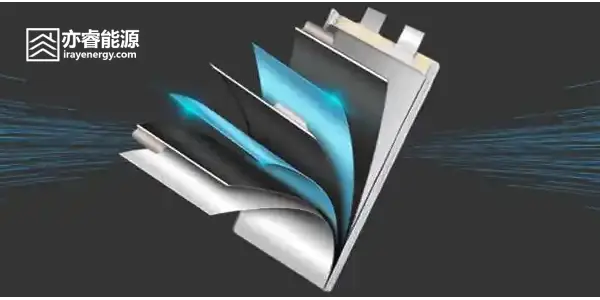

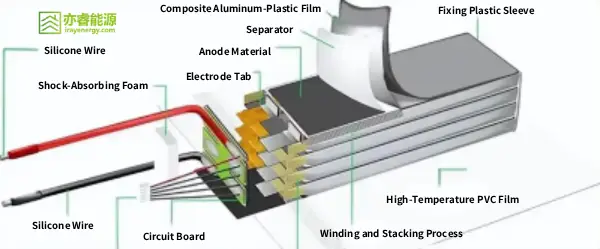

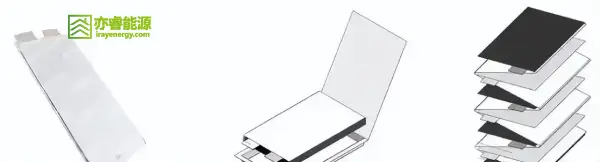

Basic Structure of the Cell

The cell is the core of the battery, mainly composed of four key parts: the cathode, anode, separator, and electrolyte. The cathode can be made from different materials, each with unique characteristics. The anode usually adopts graphite or similar materials. The separator acts as a loyal guardian, building a solid barrier between the cathode and anode to effectively prevent short circuits. The electrolyte functions like a “highway” for lithium ions, ensuring smooth transport during charging and discharging, thus keeping the process orderly.

Comparison of Different Brands of Cells

On the market, different brands of cells show significant differences in performance, quality, and cost. Some well-known brands excel in consistency, where key parameters like capacity and internal resistance vary very little within the same batch. This consistency is crucial for battery pack performance and safety. For example, Panasonic cells are renowned for their high energy density and stability, while Samsung cells also hold a large market share and are recognized for their reliability and strong performance.

Criteria for Selecting Cells

When selecting cells, multiple factors must be considered. First, the performance parameters must match the actual needs of the drone, such as energy density and discharge rate. Energy density determines how much energy can be stored, while the discharge rate affects whether the battery can release sufficient power within a short time—for example, during takeoff or high-speed flight. Quality and stability are equally important, favoring reputable brands with mature production processes. Cost must also be balanced, aiming to achieve the best trade-off between performance and price.

Indispensable Connection Components — Wiring Harness

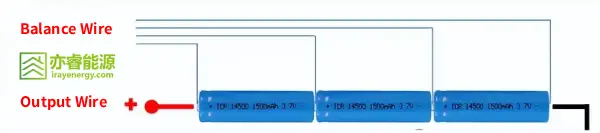

Function and Importance of Output Wires

Output wires are responsible for transmitting the battery’s electrical energy to key devices such as the drone’s motors and flight controller. Their conductivity directly affects transmission efficiency. If the resistance of the output wire is too high, excessive heat may be generated, causing unnecessary energy loss, line failures, and even disrupting normal flight.

Role of Voltage Monitoring Wires (Balance Wires)

Balance wires primarily monitor the voltage of each cell in the battery pack. During charging and discharging, due to internal resistance and other factors, voltage differences may arise between cells. The balance wires act as sensitive sensors, transmitting each cell’s voltage data to the Battery Management System (BMS). If the voltage difference exceeds a set range, the BMS quickly activates balancing, ensuring each cell operates within a safe range. This process extends battery life and significantly enhances stability and safety.

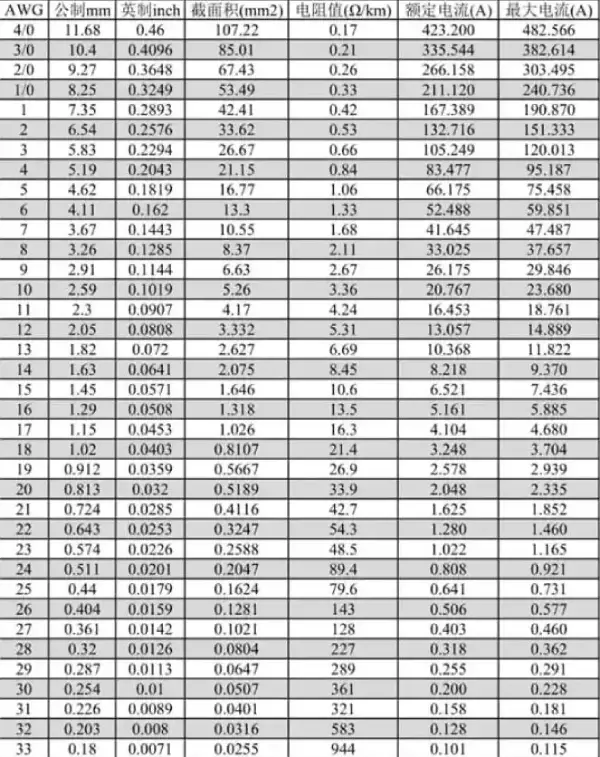

Wire Gauge Selection and Calculation

Wire gauge must be precisely determined based on the maximum discharge current. In general, higher current requires thicker wires to reduce resistance and ensure efficiency and safety. Wire gauge calculation relies on electrical formulas, referencing acceptable voltage drop and material resistivity. For drone batteries requiring high current discharge, thicker wires such as 12AWG or above may be necessary to guarantee stable transmission.

The Key to Reliable Connections — Connectors

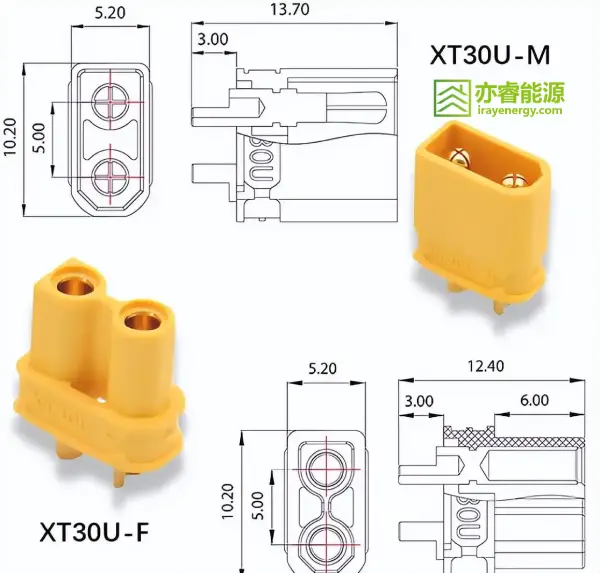

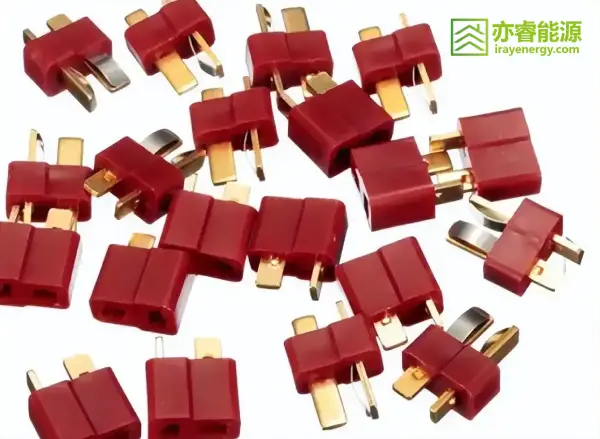

Common Connector Types (e.g., XT60)

In drone battery applications, many connector types exist, with XT60 being one of the most widely used. It offers multiple advantages: easy plug-in/out, extremely low contact resistance, and high current handling capacity. Its design ensures a tight male-female fit, avoiding looseness or poor contact. Besides XT60, other types like XT30 and T-plugs serve different power and current needs, covering diverse applications.

Connector Selection and Usage Precautions

When selecting connectors, both the discharge current and drone interface type must be considered. The rated current of the connector must exceed the battery’s maximum discharge current to prevent overheating or burning. During operation, proper insertion and removal techniques are critical—forcing may damage the connector. Regular checks are also important, cleaning off oxidation or dirt to maintain conductivity.

Connector Installation and Maintenance

During installation, welding quality is essential. Soldering must be solid, eliminating the risk of cold joints. After welding, connections should be inspected to ensure smooth, strong solder joints with no short-circuit risks. In maintenance, cleaning dirt and applying conductive grease can prevent oxidation and enhance conductivity. If damage or poor contact is detected, connectors should be replaced immediately.

The Battery’s Smart Assistant and Supporting Devices

Battery Management System (BMS)

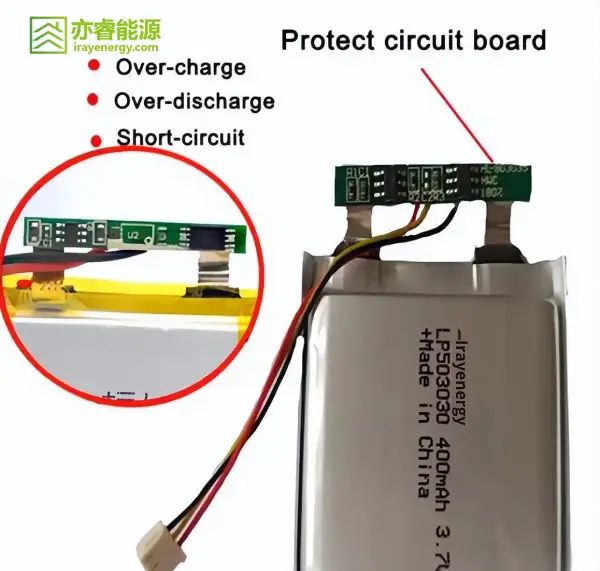

Functions and Roles of the BMS

Known as the “intelligent manager” of the battery pack, the BMS has powerful features. It monitors voltage, current, and temperature in real time, ensuring safe operation and preventing overcharge, over-discharge, or overheating. For example, if voltage nears the overcharge threshold, the BMS cuts off charging to prevent damage. The BMS also balances individual cells, keeping voltages consistent and improving performance and lifespan.

How to Select the Right BMS

Choosing a BMS requires careful consideration. First, its rated voltage and current must match the battery pack’s specifications (voltage, capacity, discharge rate). The BMS should have accurate voltage monitoring and effective balancing strategies. Brand reputation and after-sales support are also critical, as reliable BMS products ensure stable and safe operation.

Working Principle and Protection Mechanism of the BMS

The BMS works through precise monitoring and control mechanisms. It uses sampling resistors for voltage/current data and sensors for temperature monitoring. When detecting abnormal conditions like overcharge, over-discharge, overcurrent, or overheating, it triggers MOSFET switches to cut off or adjust circuits, protecting the battery. For instance, in overcurrent events, the BMS disconnects output instantly to prevent damage.

Charger

Types of Chargers (e.g., Smart Charger, Balance Charger)

There are many charger types, with smart chargers and balance chargers being the most common. Smart chargers can automatically recognize battery parameters and adjust charging voltage/current accordingly, offering ease of use and protection. Balance chargers independently charge each cell, ensuring voltage consistency, thus enhancing performance and extending lifespan.

Choosing and Using Chargers

Charger selection must align with the battery’s type, capacity, and charging rate. For example, a 3S battery requires a charger output of around 12.6V, with charging current selected based on capacity and safe charge rate. Proper procedure must be followed: connect the battery before powering the charger, and disconnect the charger from power before unplugging the battery.

Charging Safety Precautions

Charging must follow strict safety measures. Avoid high-temperature environments, as heat degrades performance and may cause hazards. Never use low-quality chargers with inaccurate parameters, which can lead to overcharging or damage. Supervision is mandatory—if overheating, smoke, or other issues occur, charging must stop immediately and emergency action should be taken.

Other Accessories

Suitable Charging Cables

In practice, many chargers use universal connectors like banana plugs, while batteries often use XT60 connectors. In such cases, adapter cables are required to bridge the mismatch, ensuring proper charging.

Battery Storage Box

Battery storage boxes are crucial for safe storage and transport. Made from fireproof and anti-static materials, they feature partitions to secure batteries and prevent damage from vibration. They also protect against compression, impact, or short circuits. For long-term storage, keeping batteries in storage boxes within suitable environments helps preserve performance and extend life.