Battery Manufacturing Process | Causes of Particle Formation During Coating and Improvement Measures

The coating process is one of the most critical steps in lithium battery manufacturing. However, particle issues frequently occur during this stage, causing significant challenges in production. This article analyzes the causes of particle formation during coating and explores corresponding solutions.

1. Causes of Particle Formation in Lithium Battery Coating

1.1 Slurry Factors

Insufficient mixing: Lithium battery slurry is a mixture of multiple components. If the mixing time is too short or the mixing intensity is inadequate, these components cannot be uniformly dispersed, which can easily lead to particle agglomeration.

Raw material particle size issues: The raw materials used—such as active materials, conductive agents, etc.—may have an uneven particle size distribution or contain oversized particles. These larger particles are difficult to disperse uniformly during subsequent processing and tend to become prominent during coating, resulting in visible particle defects.

Slurry sedimentation: When slurry is left standing for extended periods, gravity causes components with different densities to settle, leading to phase separation. This can create regions with high particle concentrations, which in turn cause particle defects during the coating process.

1.2 Equipment Factors

Inadequate cleaning of coating equipment: If residual dried slurry, impurities, or other contaminants from previous production runs remain inside the coater, they can mix with the new slurry during the coating process. These contaminants may then be deposited onto the electrode surface, resulting in particle defects.

Filter malfunction: During slurry transport, filtration systems are used to remove large particles and impurities. If the filter malfunctions—such as due to a damaged or clogged mesh—it can fail to effectively filter the slurry. As a result, oversized particles may pass through and cause particle formation during coating.

1.3 Environmental Factors

Low cleanliness of the production environment: If the cleanliness level of the production area does not meet required standards, airborne dust, particles, and other contaminants can easily enter the slurry or settle directly on the electrode during the coating process, resulting in particle defects.

Improper temperature and humidity control: Fluctuations in temperature and humidity can affect the properties of the slurry. Excessive humidity may cause some raw materials to absorb moisture, leading to particle agglomeration. Temperature variations can alter the slurry’s viscosity and flow characteristics, indirectly contributing to particle formation during coating.

2. Solutions to Particle Formation in Lithium Battery Coating

2.1 Optimizing Slurry Preparation Process

Extend mixing time and increase mixing intensity: Based on the characteristics of the slurry, appropriately extend the mixing time to ensure thorough and uniform dispersion of all components. At the same time, moderately increase the mixing intensity, while being careful to avoid breaking particles or causing new agglomeration due to excessive shear force.

Strictly control raw material particle size: During raw material procurement, conduct rigorous screening and inspection of the particle size distribution of active materials, conductive agents, and other components to ensure they meet production requirements.

Prevent slurry sedimentation: Add an appropriate amount of anti-settling agents during slurry preparation to improve suspension stability. Additionally, use continuous stirring or periodic agitation methods to avoid long-term standing of the slurry, thereby reducing the risk of sedimentation.

2.2 Enhancing Equipment Maintenance and Management

Regular cleaning of coating equipment: Establish strict cleaning protocols to ensure thorough cleaning of the coater after each production run. This includes cleaning critical parts such as the slurry tank, coating head, and pipelines to eliminate any residual slurry and prevent impurity buildup.

Timely replacement and maintenance of filtration systems: Regularly inspect the condition of filtration devices and promptly replace damaged filter meshes. Based on actual production needs, adjust the filtration precision appropriately to effectively remove large particles and impurities while ensuring smooth slurry delivery.

2.3 Improving Production Environment Conditions

Enhance cleanliness of the production environment: Install air purification systems, such as HEPA (High-Efficiency Particulate Air) filters, to purify the air in the production workshop and reduce the concentration of dust and airborne particles. At the same time, strengthen workshop sealing and contamination control measures to minimize the intrusion of external pollutants.

3. Conclusion

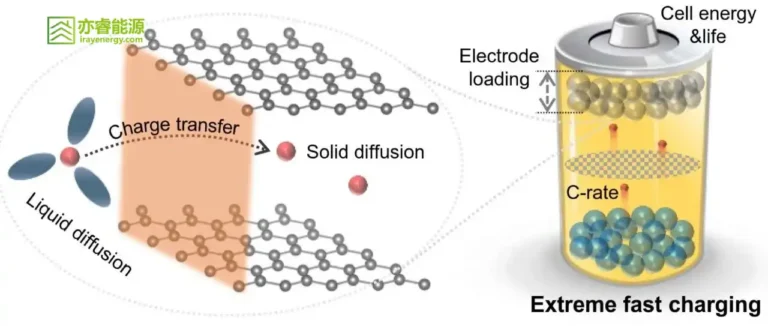

Particle defects during the coating process have a significant impact on the performance and quality of lithium batteries. By thoroughly analyzing the contributing factors—such as slurry preparation, equipment condition, and environmental cleanliness—and implementing targeted improvement measures, the occurrence of coating particles can be effectively reduced, leading to enhanced coating stability and overall product consistency.