Cell Aging vs. PACK Aging: What’s the Difference Between These Two Aging Tests?

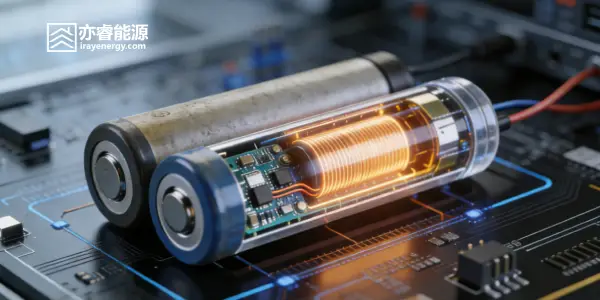

In the battery manufacturing process, aging testing is a critical step to ensure product quality and safety. However, when customers learn about battery production, a common question often arises: What is the difference between cell aging and PACK aging? Are both really necessary? In fact, cell aging and PACK aging focus on different aspects. They…